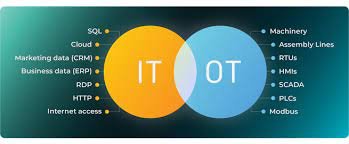

IT focuses on managing electronic data, while OT controls physical processes and equipment.

IT is essential for business operations and decision-making and involves the use of computers and software to gather, store, process, and share data securely. OT employs hardware and software to monitor and control industrial operations, ensuring efficiency and safety in sectors like manufacturing and energy.

What Is Information Technology (IT)?

Information Technology (IT) encompasses the tools and processes used to manage electronic data. It involves the use of computers, software, and networks to gather, store, process, and share this data securely and efficiently.

IT ensures the reliable operation of technology, facilitating timely access to accurate and secure information. The field is central to modern business operations, aiding in the quick and precise execution of tasks, analyzing data, decision-making, and the secure exchange of information.

What Is Operational Technology?

Operational Technology (OT) is the integration of hardware and software dedicated to monitoring and controlling physical devices and processes within industries such as manufacturing, energy, and telecommunications.

It employs specific technologies like Industrial Control Systems (ICS) and Supervisory Control and Data Acquisition (SCADA) to manage, monitor, and automate industrial operations in real-time. Legacy systems are common in OT, though advancements in technology are leading to more modern integrations.

OT is instrumental in enhancing the efficiency, safety, and reliability of industrial processes by providing immediate feedback and control options, minimizing downtime and maximizing productivity.

It is distinct from Information Technology (IT) as it directly interfaces with industrial equipment and processes, focusing on the physical environment and operational needs.

What Are the Differences Between IT and OT?

Purpose and Focus

IT focuses on managing and processing data, ensuring its availability, confidentiality, and integrity. It deals with the storage, retrieval, and transmission of data, ensuring that information is accessible and secure. OT is dedicated to controlling and monitoring physical processes and equipment, playing a crucial role in critical infrastructure. It ensures that machinery and processes operate effectively and safely.

Environment

IT operates in a general computing environment, managing devices like computers, servers, and smartphones. It involves standard operating systems and is centered around data-centric tasks. OT operates in industrial environments, managing specialized equipment and processes. It uses customized, often proprietary systems tailored to specific operational needs.

Security Concerns

OT security, however, prioritizes the safety and availability of industrial systems and processes. The integrity and continuous operation of physical equipment are paramount in OT, given that a failure can result in significant safety and financial implications. Both IT and OT make use a range of security tools for these objectives.

What Is OT Security?

System Updates and Maintenance

IT systems are regularly updated to patch vulnerabilities and enhance performance, with established schedules for updates. OT systems, conversely, aren’t typically updated as frequently. Interruptions for updates in the OT environment can halt production, so patches are applied during specific maintenance windows to avoid disrupting ongoing operations.

Connectivity

IT is inherently connected, facilitating data exchange and communication over networks, including the internet. OT has traditionally been isolated, with systems not designed for external connectivity. However, the advent of Industrial Internet of Things (IIoT) is bridging this gap, integrating OT systems with broader networks for enhanced data analytics and operational efficiency.

Data Use and Processing

IT deals with a variety of data types, including transactional, voice, and bulky data, focusing on the broad business needs of data storage, processing, and communication. OT, in contrast, is centered around real-time data processing to monitor and control physical devices and processes. The immediacy and specificity of data use in OT are critical to ensuring operational efficiency and safety.

Differences in System and Devices Explained

The Blurring of IT and OT Leads to Operational Visibility

Information technology (IT) has been a critical component in the success of manufacturing companies for decades. With it, companies have improved processes and added automation that tapped into the best technology available.

But technology is on the move, and the extensibility of data from the machinery and equipment that runs industrial control systems in the form of operational technology, or OT, has caught up with IT systems.

Combined with the Industrial Internet of Things (II0T), the ability to collect data and control physical devices on industrial equipment has revolutionized the concept of manufacturing, enabling deep visibility across operations.

Within this article, we explain the concepts of IT and OT, and discuss the primary differences among IT vs. OT systems, devices, and security.

Device Specification

Early IT interaction with machines was primarily used to gather data in a one-way manner. Data was collected and sent to in-house servers to be accessed by programs like ERP systems. As machine automation grew, the heavy use of programmable logic controllers (PLC) meant that there was often some degree of interaction with a programmed device that triggered an action.

These devices, like PLCs, required on-site or PC-based programming and often used closed communications protocols limiting the use of other devices on the network.

The MachineMetrics Edge device connects to a PLC to collect data, standardize the information, and send it to the cloud. This is an example of the overlap of OT and IT, as the operational technology data can now be consumed in cloud-based applications, such as an ERP or MES. MachineMetrics helps to bridge this gap, ensuring complete visibility of the shop floor.

Adopting the EtherNet/IP protocol and creating open-source protocols such as DeviceNet and ControlNet meant that OT devices from different vendors could be configured to allow faster, real-time data collection.

This device transformation has advanced, along with IIoT technology, the move to cloud-based IT, and the arrival of Big Data through AI and ML to bring IT and OT closer together. Now, rather than two systems that can’t effectively operate and communicate together, IT and OT are best viewed as “layers.” These layers consist of business functions and machine data layers, with OT working with IIoT technologies.

As they’re meant to move data without other requirements, IT devices are often more straightforward to maintain than OT devices. They may also have a shorter lifespan and operate with standard OS systems such as Windows or Linux.

OT devices have specific purposes for control and data acquisition. Because they’re critical to safety and machine condition, they’re very reliable and can operate around the clock for many years without failure or replacement. OT devices are also smaller and more modular to integrate into a production machine.

Most OT devices have a variety of network interfaces and communication protocols not used in IT. This includes Modbus, CIP, and Profinet. This variety allows them to work with most of today’s IoT applications seamlessly.

Distinctions Between IT and OT?

IT focuses on the fact that there is data, and OT focuses on what it means and how it can optimally drive connected assets. Other critical distinctions between IT and OT include:

- Device Maturity: It’s simpler and easier to manufacture. OT devices represent a constantly changing collection that works to keep pace with new advances in digital technologies. As this cross-field communication requirement between the two increases, it will be critical for IT teams and OT departments to work together to program a converged system for optimization.

- Cost: Many companies with legacy IT networks balk at the expense of another CAPEX undertaking that carries with it a significant learning curve for new technology. Having invested in cables, servicers, fiber, and skillsets, some are wary of the move to the cloud, much less OT and industrial IoT. But entry costs to both OT devices and industrial IoT platforms have dropped significantly. And when combined with productivity gains and lower total cost of ownership over time, the ROI for cloud-based machine monitoring devices and platforms is considerably lower than long-term maintenance of traditional IT.

- Data Management: OT focuses on the processing of data in real-time. IT focuses on transactional data that may consist of office communication, video processing, and large chunks of unstructured data.

- Safety: If an IT device fails, the most significant effect is data loss that could affect the business. However, because OT monitors physical assets, it can help prevent costly catastrophic machine failure.

IT vs. OT Security Threats

IT has always been security conscious, and companies have invested a lot in securing their networks. However, cloud-based security has become significantly more robust. Today, the greatest threat to the IT side is the same as when networks were in-house; passwords, access, and authorization protocols are a more significant threat to cloud-based data than attacks.

OT began as disconnected from the outside world. But with the rise of IoT in the Fourth Industrial Revolution, OT devices became more vulnerable to external attack. Many OT security initiatives focus on the application layer to control access. In contrast, IT looks to secure enterprise data to protect employee safety and ensure the continuous operation of connected assets.

Security threats will continue, challenging OT teams with more advanced attacks.

What is IT and OT Convergence?

IT and OT convergence represent a unified system that offers comprehensive data management, monitoring, and control. With agnostic and open device and IoT platforms like MachineMetrics, companies can leverage the best of their assets without additional costly infrastructure.

Such systems can work with legacy IT for in-house or cloud-based platforms. Monitoring and controlling industrial assets at the operational level feed data to the enterprise level IT functionality, and both benefit from advanced analytics, AI, and machine learning algorithms.

The result is a streamlined system offering a single version of truth for companies utilizing IIoT technology.

What Are the Similarities Between IT and OT?

Operational Efficiency

Both IT and OT seek to enhance operational efficiency within organizations The convergence of IT and OT amplifies operational efficiency, leveraging data analytics and automation.

Advanced Technology Adoption

IT and OT are both adopting modern technologies like artificial intelligence, machine learning, and cloud computing. These technologies are enhancing data analytics, automation, and decision-making processes in both domains, leading to improved efficiency and greater innovation.

Interdisciplinary Skills

The workforce in both IT and OT is becoming more interdisciplinary. There is a growing need for professionals who understand both domains to facilitate seamless integration, manage cybersecurity effectively, and optimize the benefits derived from the convergence of IT and OT.

Comparing OT vs. IT Devices

IT devices are built for collecting and sending data to servers. They are straightforward, initially designed for one-way data transfer. In contrast, early OT devices, like Programmable Logic Controllers (PLCs), were focused on tasks done on-site or through PC-based programming, with limited communication capabilities.

Communication between these devices improved with the introduction of new communication protocols like EtherNet/IP, DeviceNet, and ControlNet. These protocols allowed OT devices to exchange data in real time and work together more efficiently. As a result, IT and OT started to merge, leading to better visibility and efficiency in operations.

IT devices, which are typically easier to maintain, have a shorter lifespan. They use common operating systems like Windows or Linux and are designed for general tasks like data processing and communication. OT devices, on the other hand, are made for specific control and data tasks. They are reliable and can work non-stop for many years without failing.

OT devices are also known for their durability. They are designed to withstand harsh conditions like heat, moisture, and vibration, making them suitable for industrial environments. This is in stark contrast to IT devices, which are not built to endure such challenging conditions. OT device design ensures effective integration with industrial machinery and processes.

The integration of IT and OT is often described in terms of layers. Business functions and machine data layers are becoming interconnected, in part due to advancements in Industrial Internet of Things (IIoT) technology. This integration marks a shift from isolated operations to a more connected approach where IT and OT work together.

IT and OT Convergence

The integration of Information Technology (IT) and Operational Technology (OT) is a transformative progression in the technological landscape, marking the intersection of digital and physical systems. Historically, IT and OT operated as distinct entities, each serving different organizational functional roles.

However, this separation is changing, largely due to the advent and proliferation of technologies like the Industrial Internet of Things (IIoT) and big data analytics. The onset of Industry 4.0 is also a major driver.

This convergence is facilitating a symbiotic relationship where real-time data from OT systems is fed into IT for in-depth analytics and insights. The integration of the digital and physical world offers organizations a holistic, 360-degree view of operations.

IT and OT convergence have challenges, like security and technology compatibility issues. Addressing these challenges requires strategic investment in compatible technologies, comprehensive security controls and protocols, and workforce upskilling to navigate the integrated landscape effectively.

Why IT and OT Teams Must Collaborate

The collaboration between IT and OT teams is essential in the modern business environment.

Security is a primary benefit, with IT’s expertise in cybersecurity proving invaluable to increasingly interconnected OT networks. IT’s experience in mitigating security risks strengthens OT’s defense mechanisms, protecting critical operational systems. The wealth of data generated from OT’s monitoring activities becomes actionable with IT’s data analytics capabilities, leading to enhanced operational efficiency.

Technical alignment achieved through the collaboration of IT and OT ensures that integrated systems are compatible, efficient, and secure. The insights and expertise of both teams contribute to a unified strategy that maximizes integration benefits. Working together is vital for capitalizing on the opportunities presented by the interconnected, data-driven industrial landscape, ensuring the organization can innovate and adapt effectively.

IT vs. OT FAQs

The connection between OT and IT lies in the integration of systems that manage and process data (IT) with those controlling industrial operations (OT). This union facilitates real-time data sharing, enhancing the efficiency and decision-making processes in various industries.

IT is the technology backbone of any organization. It’s necessary for monitoring, managing, and securing core functions such as email, finance, human resources (HR), and other applications in the data center and cloud. OT is for connecting, monitoring, managing, and securing an organization’s industrial operations.

It combines technologies for networking, information processing, enterprise data centers, and cloud systems to manage data and applications. Meanwhile, ‘OT’ refers to hardware and software that detects or causes change through the direct monitoring and/or control of industrial equipment, assets, processes and events.